New Ideas for Solving the Tag Problem: Why is this gun glue needle a popular choice in the apparel industry?

In the competitive apparel industry chain, every tiny link may affect the overall operational efficiency. In the face of frequent replacement of product labels, complicated packaging processes, and growing customer demand, traditional tools have been unable to meet the ever-increasing pace of work.

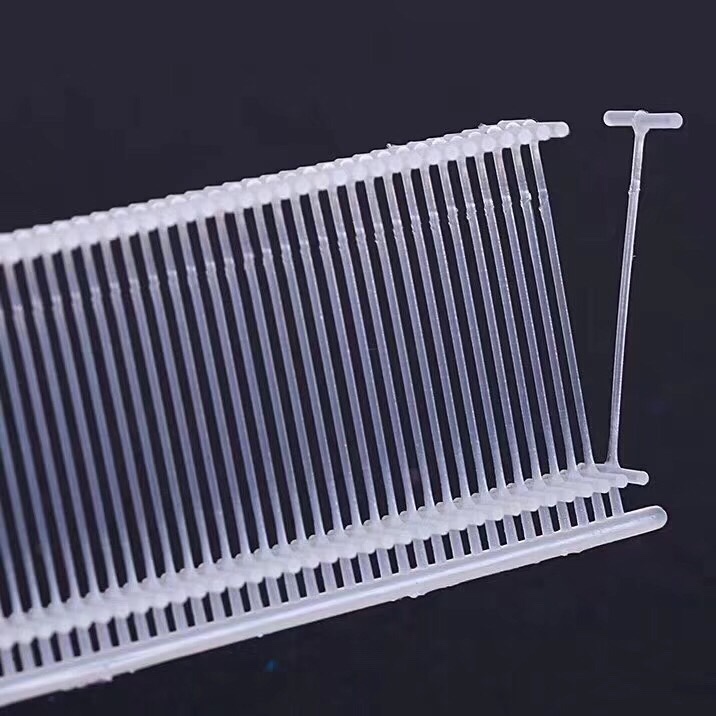

Now, a 15cm gun glue needle specially tailored for tag operation is quietly changing this situation. With its excellent load-bearing capacity and simple operation mode, once launched, it has been widely welcomed by the industry and has become a standard accessory adopted by major brands and manufacturers.

The power behind innovative design: the charm of the transparent round-headed pointed dual-mode combination

The traditional single-head design can only deal with a single type of fabric structure, which is easy to cause the problem of Caton or damage to the fabric. This 15cm long gun glue needle has a breakthrough fusion of two completely different head shapes-one side is a round end that firmly locks the knot, and the other side is a sharp and easy-to-penetrate tapered tip.

this ingenious idea makes it not only can firmly tie the ribbon, hemp rope and other suspension parts, but also can easily pass through thick denim or light silk yarn, and still be able to handle all kinds of extreme environments, showing excellent adaptability.

Eco-friendly materials create a quality model: how do PP raw materials protect the bottom line of safety and sustainable development?

In response to the global trend of green manufacturing, this series of gun glue needles select high-quality polypropylene (Polypropylene) as the core raw material. This is an engineering plastic certified by international food safety standards, with good impact resistance and chemical resistance.

More importantly, these materials can be recycled and do not contain any toxic and harmful substances, even if long-term contact with human skin will not cause allergic reactions. This means that while pursuing economic benefits, enterprises can also fulfill their social responsibilities and promote the industry to a new era of low-carbon environmental protection.

more than a tool upgrade: understand the profound impact of a small glue needle on store management

Although it is only a small auxiliary part, its significance is far beyond imagination. When all stores use the same specifications of the gun glue needle, not only can reduce the rework caused by size differences, but also simplify the staff training process, thus saving a lot of manpower and time costs.

At the same time, thanks to the high consistency and stability, enterprises can also plan inventory quantity more scientifically, control the loss ratio, and then optimize the annual budgeting system, so that supply chain management has become more orderly than ever.

The voice of front-line users is the most authentic: the actual experience sharing from retailers and manufacturers from all over the world

"in the past, every time a new product was introduced, it was necessary to repeatedly check whether the tag was firm, for fear of returning the goods due to falling. Now, after changing this batch of new gun glue needles, there has been almost no disconnection or slippage." So says the regional manager of a large apparel chain.

the person in charge of a number of processing plants also said that after the introduction of this series of products in large quantities, the packaging speed of the production line has been significantly accelerated, especially during the peak period of orders such as Double Eleven and Spring Festival. It can be seen that this is not only an efficient office supplies, but also an important supporting force for stable business operation.