From a large factory assembly line to a small family studio, a small gun glue needle is quietly changing the traditional process. Especially in the field of clothing tags, this 15cm long PP pointed hand threading needle has quickly become a popular choice in the industry due to its light, flexible, durable and efficient characteristics.

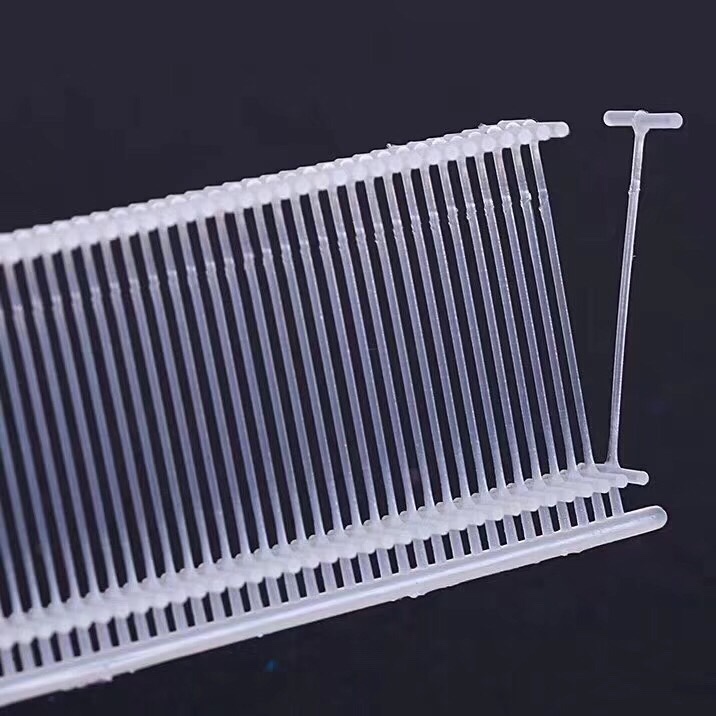

As a modern hand tool, the core competitiveness of this gun rubber needle lies in its high-quality materials and exquisite design. Made of high-strength PP (polypropylene), it not only has excellent flexibility and anti-fracture ability, but also has the advantages of environmental protection and non-toxicity, which is very suitable for long-term frequent use. In addition, the transparent round head design makes the operation more intuitive and convenient, reduces the work error caused by the line of sight blocking, and greatly improves the work efficiency.

In order to further adapt to different application scenarios, this 15cm gun glue needle pays special attention to detail polishing. The sharp but not sharp head can accurately pierce various thicknesses of cloth or cardboard, while avoiding finger injury, and the longer overall length provides users with greater control and comfortable holding space. Whether it is a professional worker who needs fine processing or a family lover who loves DIY, they can benefit a lot from it.

Let's look at a set of real case studies. A well-known garment brand once faced the problems of high labor cost and technical bottleneck. After the introduction of this batch of 15cm gun glue needles, their tag assembly speed increased nearly three times, while the defective product rate decreased significantly. This change is a testament to the tremendous productivity boost from quality tools.

For users who are exposed to such products for the first time, it is important to master the correct method of use. First of all, it is recommended to wear protective gloves to avoid accidental scratches on the skin; secondly, pay attention to proper rest during repeated force movements to prevent fatigue accumulation from causing occupational disease risks. It is also necessary to regularly clean up the dirt to ensure that the equipment is always in good condition to extend the service life.

Looking to the future, with the continuous progress of science and technology and the increasingly diversified market demand, there is still a lot of potential for innovative solutions like this to be tapped. For example, by improving the existing structure or integrating intelligent sensing technology into it to achieve a higher degree of automation of the new gun glue needle and so on are expected to gradually become a reality.

in short, this 15cm gun rubber needle from Guangdong chuyi has won the trust and support of many customers with its affordable price and perfect service system. If you are also looking for an effective way to improve efficiency and reduce costs, please do not hesitate to act now!