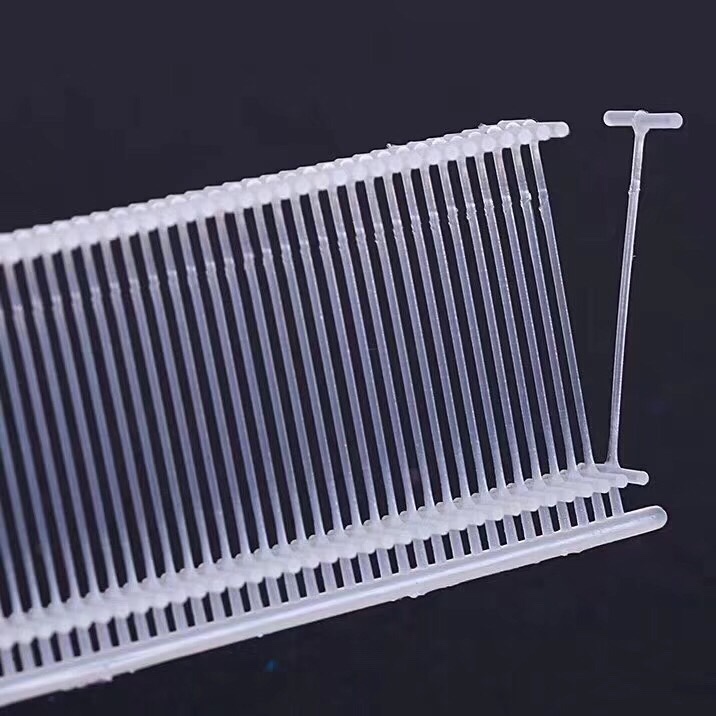

Imagine this: a rack of pristine garments, each one flawlessly tailored, thoughtfully designed, and ready for its moment under the retail spotlight. Then, your eye catches it — a crooked tag, a frayed thread, or worse, a missing label altogether. That tiny detail can quietly undermine everything. In the world of fashion, perfection isn’t just expected — it’s non-negotiable. And behind every perfectly placed tag lies an unsung hero: the 15cm Transparent PP Glue Needle.

When Efficiency Meets Elegance: The Quiet Revolution Behind Retail Perfection

In fast-paced environments — from bustling warehouse floors to high-end ateliers — attaching clothing tags is a task performed thousands of times daily. Yet, too often, it's done with tools that snag, bend, or obscure the very thread they’re meant to guide. Metal needles scratch silks. Opaque plastic ones disappear into folds. Mistakes mean rework, delays, and damaged goods. But what if the solution wasn’t a machine upgrade, but a humble rethink of the tool itself?

The 15cm Transparent PP Glue Needle emerges not as a flashy innovation, but as a quiet revolution — a simple object engineered for maximum impact. It doesn’t replace workers; it empowers them. By refining the smallest element of the tagging process, it elevates the entire standard of finish.

More Than Just a Threader: The Design Philosophy of an Invisible Ally

Made from high-clarity polypropylene (PP), this needle is both strong and supple. Its 15cm length offers extended reach without sacrificing control — long enough to navigate deep seams or layered linings, yet slender enough to remain nimble in the hand. The pointed tip pierces cleanly through fabric and tag holes without fraying, while the rounded head provides a secure grip and prevents accidental slippage.

Transparency isn’t merely aesthetic. It’s functional intelligence. As you guide the needle through a narrow loop or between tightly woven fibers, you see exactly where it’s going. No guesswork. No poking blindly. This visibility reduces errors, speeds up threading, and protects delicate materials from unnecessary stress.

Dancing Between Folds and Labels: Real-World Applications Across Industries

Watch it in a fast-fashion fulfillment center, where speed is currency. Workers zip through hundreds of garments per shift, attaching price tags with rhythmic efficiency. The needle bends slightly when needed, then springs back — no breakage, no downtime. Now picture a couture tailor in Milan, restoring a vintage piece. They use the same tool to reattach a fragile care label by hand, appreciating how it glides through silk without leaving a mark.

Even e-commerce return centers have adopted it. When a customer sends back a dress, the original tag must be carefully reattached before resale. With traditional tools, this risks damaging the neckline. With the transparent PP needle, it’s seamless — literally.

Why Designers Are Secretly Carrying One in Their Pockets

It started with a few stylists. Then boutique owners. Now, some designers tuck a single transparent needle into their leather rolls like a hidden talisman. For them, it’s more than utility — it’s ritual. A symbol of respect for craftsmanship. The act of threading a label becomes intentional, almost meditative. They’ve realized that true professionalism isn’t only about grand visions; it’s about honoring the micro-moments that shape perception.

From “Good Enough” to Effortless: The Feel of True Usability

There’s a moment — subtle but unmistakable — when you first use this needle. Your fingers close around the smooth, lightweight shaft. You guide it toward a tiny satin ribbon loop. Instead of resistance, there’s glide. No snagging. No frustration. Just clean, silent passage. Compared to cold metal that slips or thick plastic that cracks, this feels like the tool finally understands its purpose.

You don’t notice it working — which is exactly why it works so well.

A Sustainable Touchpoint in a Disposable World

In an era where sustainability shapes supply chain decisions, even small tools matter. Unlike flimsy disposable needles that snap after two uses, the PP glue needle is built to last. Durable, reusable, and resistant to moisture and corrosion, it reduces waste significantly over time. One needle can serve dozens of garments — a minor switch with measurable environmental upside.

The Triumph of Visibility: Seeing Is Believing (and Doing)

Its transparency is its superpower. You never lose it in fabric folds. You never misalign it mid-thread. You see the thread follow the path, ensuring accuracy. In training new staff, supervisors point to the needle itself as a teaching aid — “Watch how it moves,” they say. Clarity breeds confidence.

Beyond Garments: Where Else Might This Tiny Tool Shine?

Gift wrappers use it to thread ribbons through narrow slots without crushing bows. Museum conservators employ it to attach archival labels to delicate textiles. Crafters love it for beading and embroidery fixes. The applications aren’t limited by design — only by imagination.

Speed Measured in Seconds, Felt in Hours

No spreadsheets needed. Just try it once. That tag you used to wrestle with? Done in ninety seconds instead of three minutes. Multiply that by hundreds of items, and suddenly, a full workday gains back precious hours. The improvement isn’t loud — it’s cumulative, silent, and transformative.

Tools Speak Volumes — If You’re Willing to Listen

The finest garments are judged not by their loudest detail, but by the quiet ones — the stitch that holds, the tag that aligns, the thread that stays put. The 15cm Transparent PP Glue Needle may seem insignificant beside a sewing machine or a CAD sketch. But in the hands of someone who cares, it becomes a statement: that excellence lives in the details, and no part of the process is too small to deserve the right tool.

Sometimes, revolution doesn’t roar. It threads silently through silk, clear, precise, and utterly indispensable.